From 13 to 17 January, we will be at BAU 2025, the world’s leading trade fair for architecture, building materials and systems, which will be held in Munich.

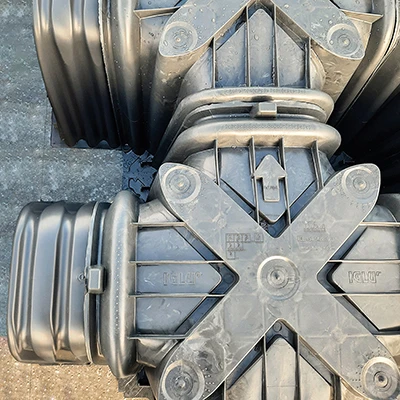

During the event, we will present our solutions for sustainable and responsible building, focusing on topics such as:

- Reducing CO₂ emissions and the amount of materials used

- Flood management

- Climate-adaptaed buildings

With our products made of recycled plastic through 100% renewable green energy production processes, we demonstrate the Daliform Group’s commitment to reducing the environmental impact of construction.

We look forward to seeing you in Hall A1 — Stand 340