In contemporary construction, the quest for innovative and sustainable solutions is increasingly paramount. Within this context, lightweight slabs with U-Bahn® Beton emerge as a high-performance and environmentally conscious choice.

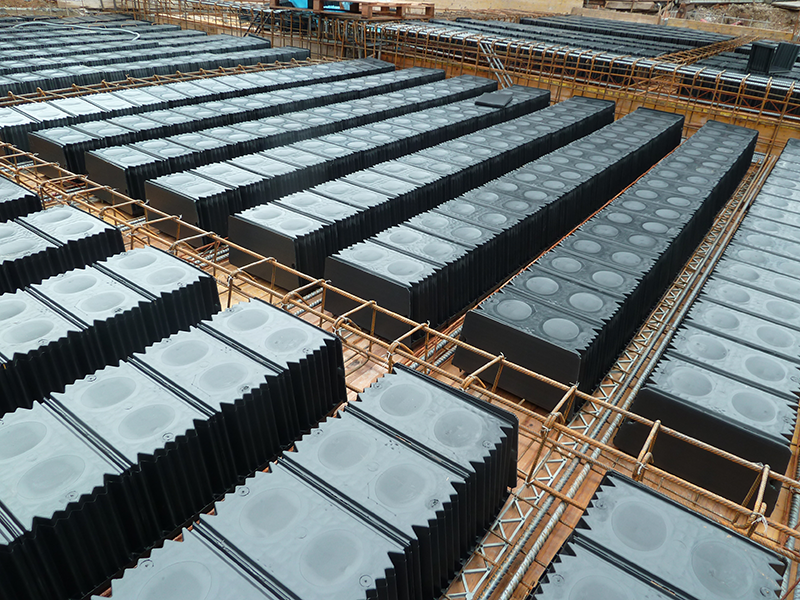

Crafted from recycled plastic, U-Bahn® Beton modular formwork exemplifies the principles of the circular economy.

The advantages of this technology extend beyond environmental benefits, offering tangible improvements in construction efficiency.

Why Choose U-Bahn® Beton for One-Way Lightweight Floor Slabs?

As a lightweight and stackable void former, U-Bahn® Beton provides exceptional design flexibility. Unlike brick piñatas and polystyrene formers, it facilitates the creation of cavities for the passage of cables and installations.

PERFORMANCE ADVANTAGES

Maximum Versatility: U-Bahn® Beton is ideal for the production of precast slabs, significantly reducing construction time and labour costs.

High Precision and Uniformity: The U-Bahn® Beton void former ensures perfect concrete rib geometry, enhancing structural performance.

Improved Site Cleanliness: Its compact and modular design minimises waste and debris on site, promoting a cleaner and safer working environment.

Enhanced Seismic Performance: The presence of a double reinforced concrete shell imparts greater rigidity and seismic resistance to U-Bahn® Beton slabs, making them ideal for areas with high seismic risk.

APPLICATIONS

U-Bahn® Beton is the optimal solution for lightweight one-way slabs in a diverse range of buildings, including residential, commercial, office, industrial structures, and public buildings such as schools and hospitals. It is particularly suited for applications that require one-way slabs and floors where minimizing structural loads is essential.

This system not only reduces the need for concrete and steel but also significantly lowers the building’s embodied carbon footprint.

A notable application is in underground construction using the «top-down» technique. Unlike traditional open-air construction that progresses from the bottom up, this method involves constructing load-bearing slabs from the top down, alternating slab construction with the excavation of lower levels.

This technique is often employed in the development of underground car parks in historic city centres, where the presence of adjacent buildings and the necessity for rapid road system restoration pose significant constraints.