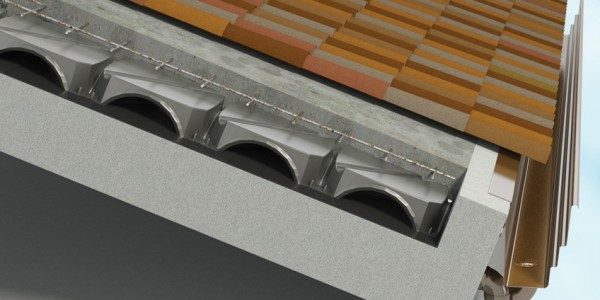

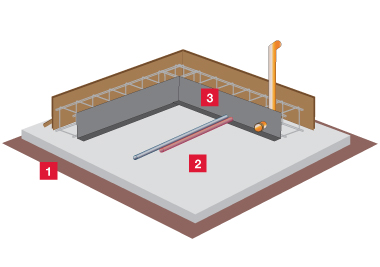

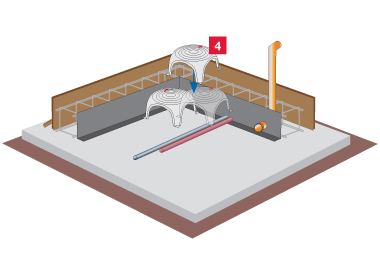

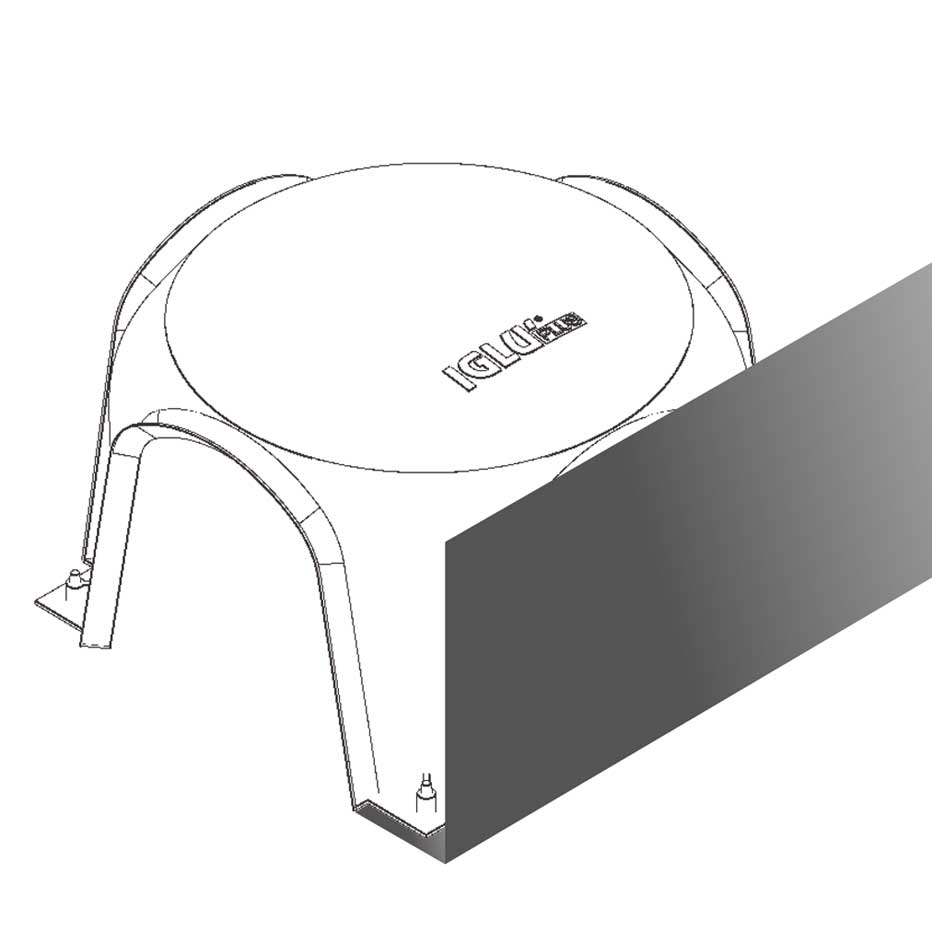

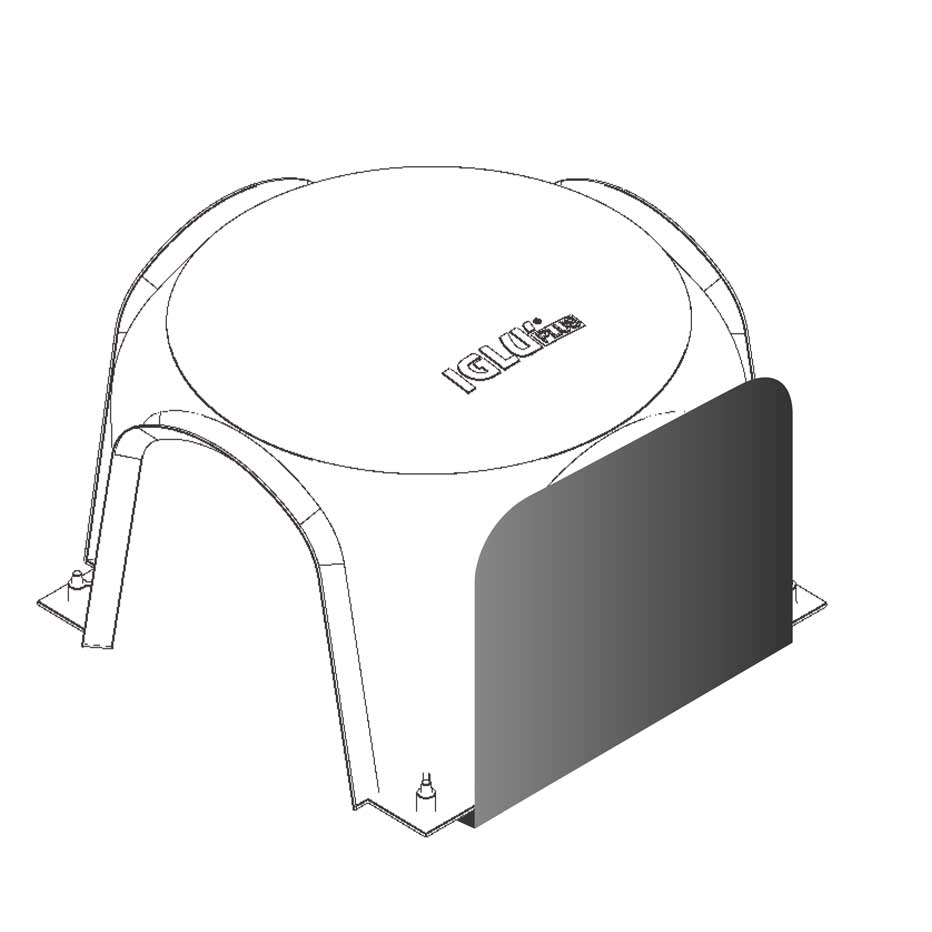

Iglu’® is a market leading product that was created and patented for the realisation of crawl spaceS, SUB-SLAB VENTILATION, ventilated cavities, ventilated floors and roofs during the construction and restructuring of civil and industrial buildings.

This result of an ingenious idea dating back to 1993 considerably improved building methods. The innovative capacity of Iglu’® has received numerous successes and recognitions on a national and international level, quickly confirming it as a product of excellence in the building world.

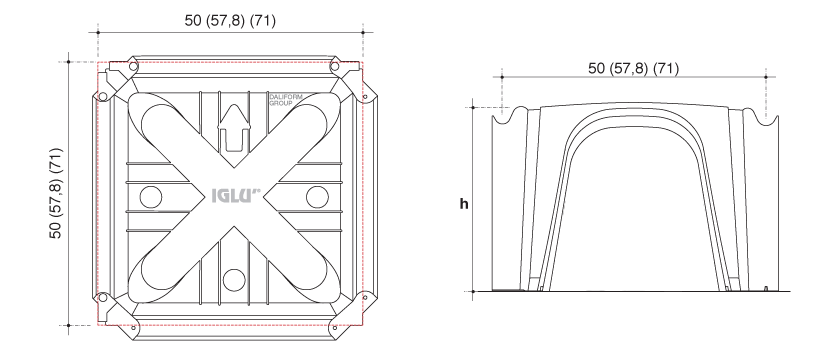

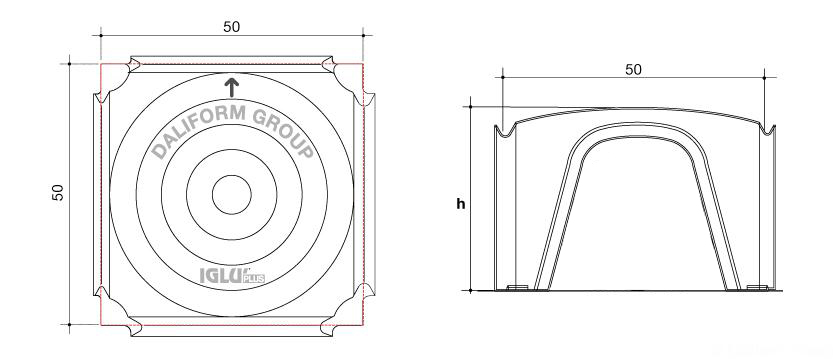

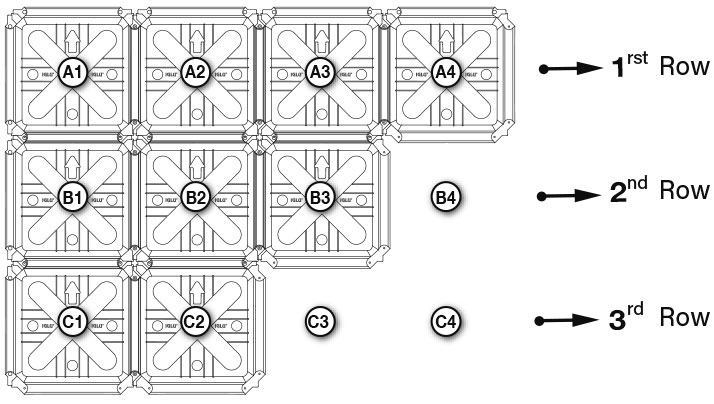

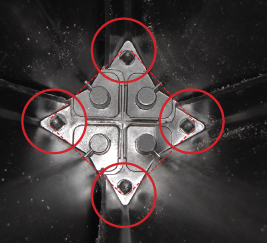

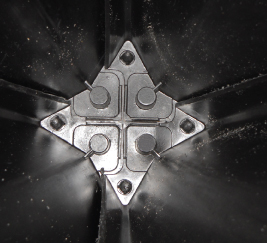

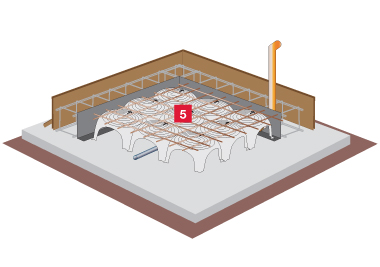

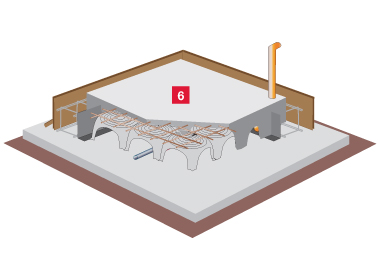

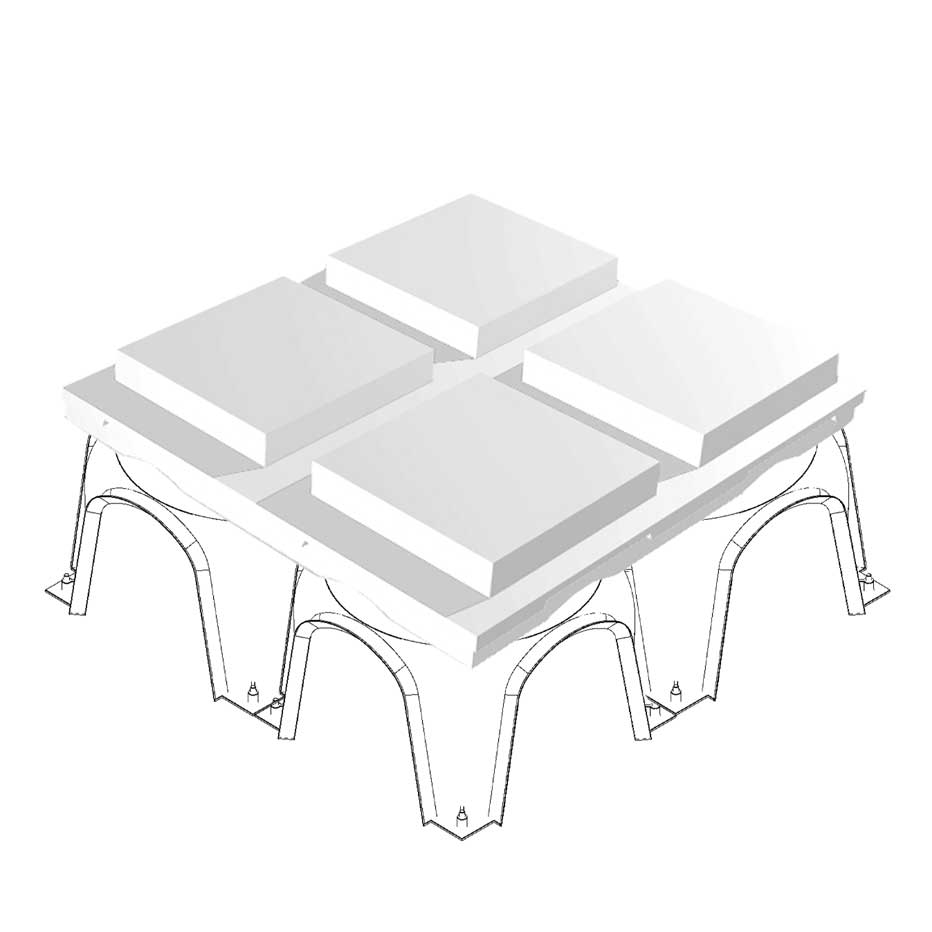

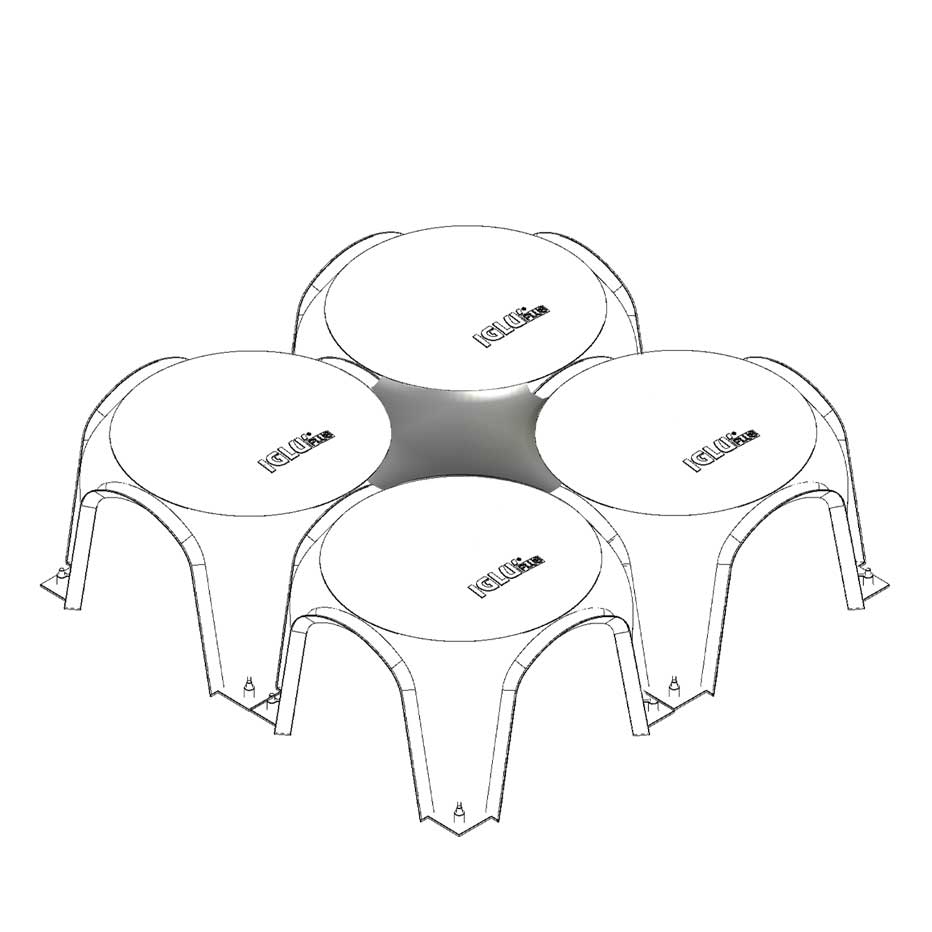

The modular recycled plastic formworks, placed side by side in sequence according to a predefined direction, make it easy to quickly create a self-supporting pedestrian platform above which a layer of is cast in order to easily and economically create a ventilated slab placed on pillars with the below cavity area available for the passage of systems but above all ventilated to counteract rising humidity and radioactive gases.