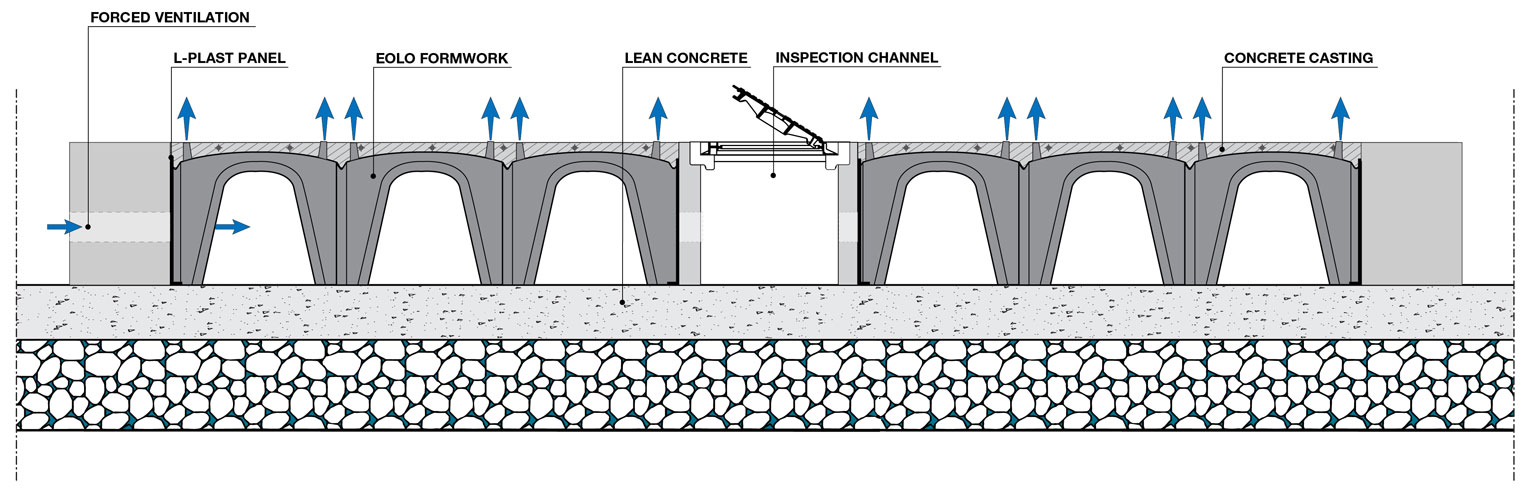

Eolo represents the efficient, fast and economic remedy for the realisation of a perforated floor in reinforced concrete with high load-bearing capacity, which can be also accessed by heavy vehicles.

Thanks to the vertical asymmetric nozzles, axially perforated, it can be conveniently used for the distribution of air in composting, waste stabilisation systems, deodorising systems and for aerating the floors of the storage rooms for the storage/curing of food products.

It is known since ancient times that storage aeration was required to avoid the formation of humidity which lead to the spreading of undisturbed mould and bacteria, deteriorating the goods (David Macaulay “La città Romana”).

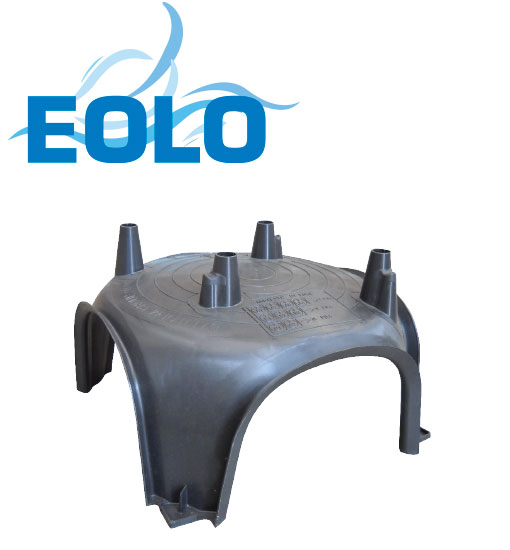

Eolo is made of recycled plastic and it is eco-compatible, and it is composed ofspecial high nozzles which permit the realisation of a 6 cm high perforated plate.

Through the Eolo elements the air is uniformly distributed in the air cavity and it is then blown into the overhead environment.