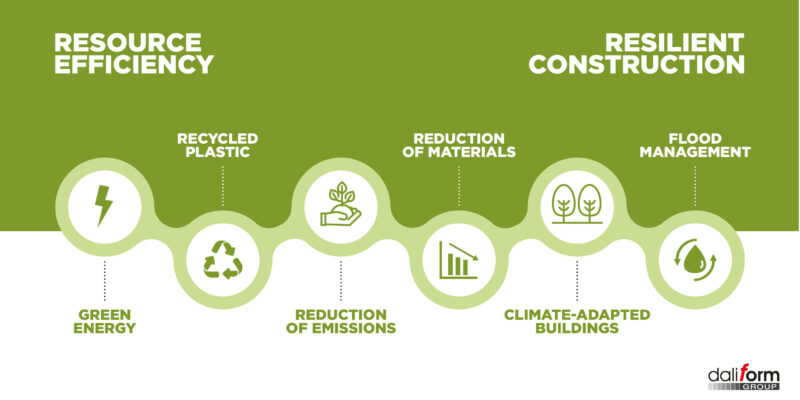

In today’s context of ever-increasing environmental and climate challenges, resource efficiency and building resilience emerge as fundamental pillars for sustainable and durable construction.

We at Daliform Group are actively committed to proposing construction solutions that are mindful of the Planet’s needs.

Our commitment to green energy

We have long since embarked on a path of energy sustainability, adopting 100% green energy for our production processes, sourced exclusively from renewable sources. This means that the energy used to produce our systems is completely CO₂-free. In this way, we actively contribute to reducing our environmental impact.

Choosing clean energy is not only an ecological choice, but also a strategic commitment to reducing harmful emissions and promoting a corporate culture geared towards environmental protection.

Using recycled plastic

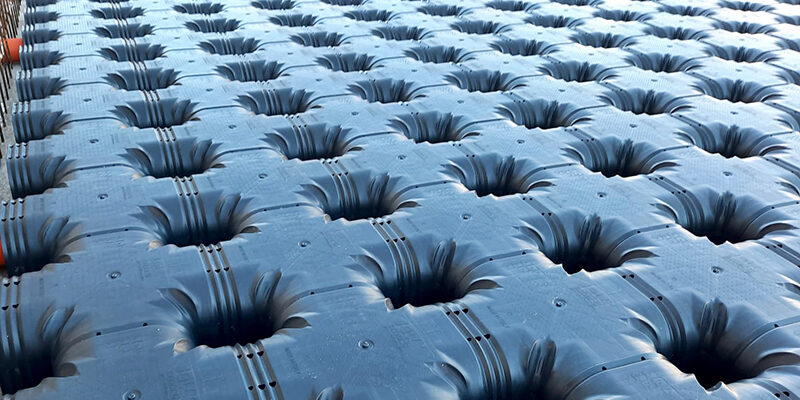

Using recycled materials, such as plastic, is the key to promoting the circular economy in the construction industry. Our products made of recycled plastic reduce dependence on virgin raw materials, lowering the overall environmental impact.

Reducing emissions

Resource efficiency is closely linked to the reduction of greenhouse gas emissions.

By implementing material efficiency strategies and adopting advanced building technologies, we contribute to buildings with a reduced carbon footprint, supporting global climate change mitigation goals.

Material savings

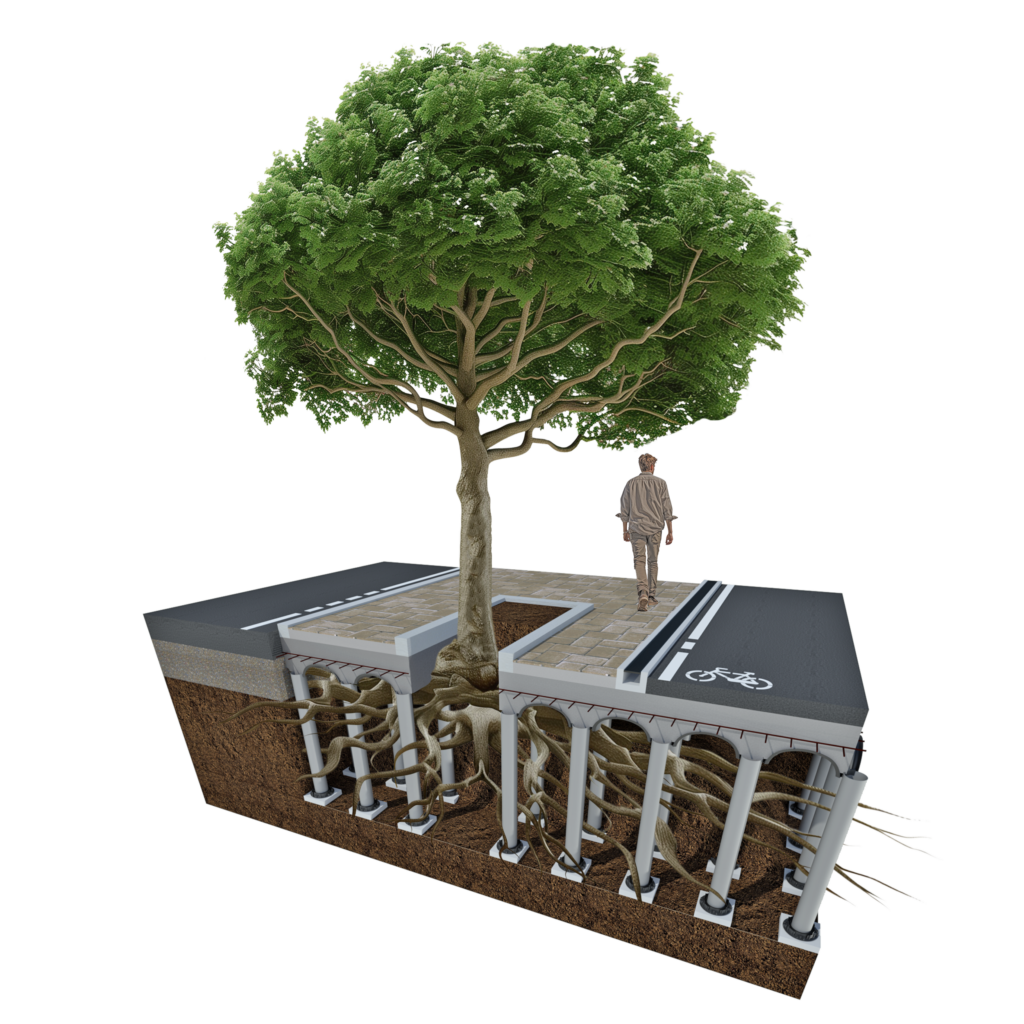

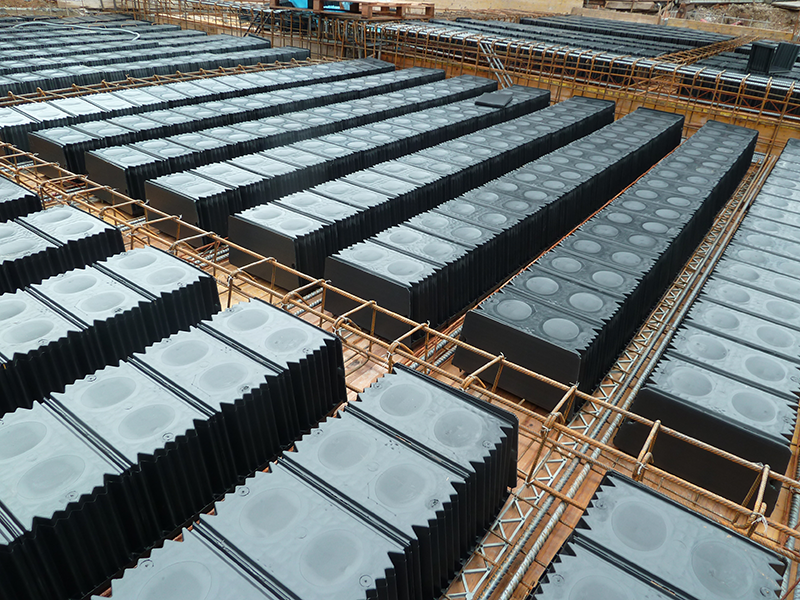

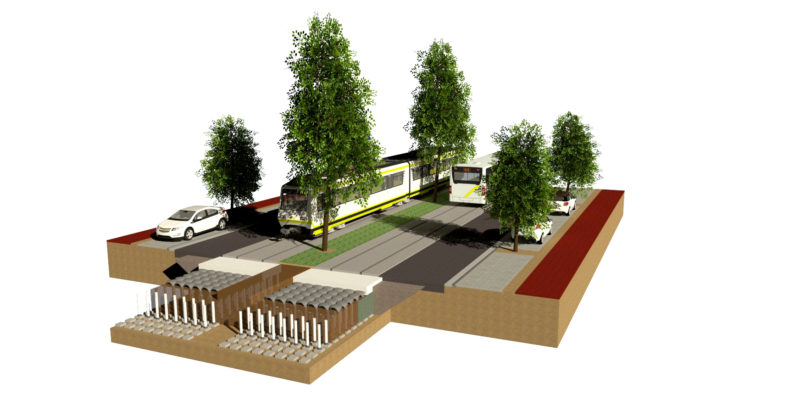

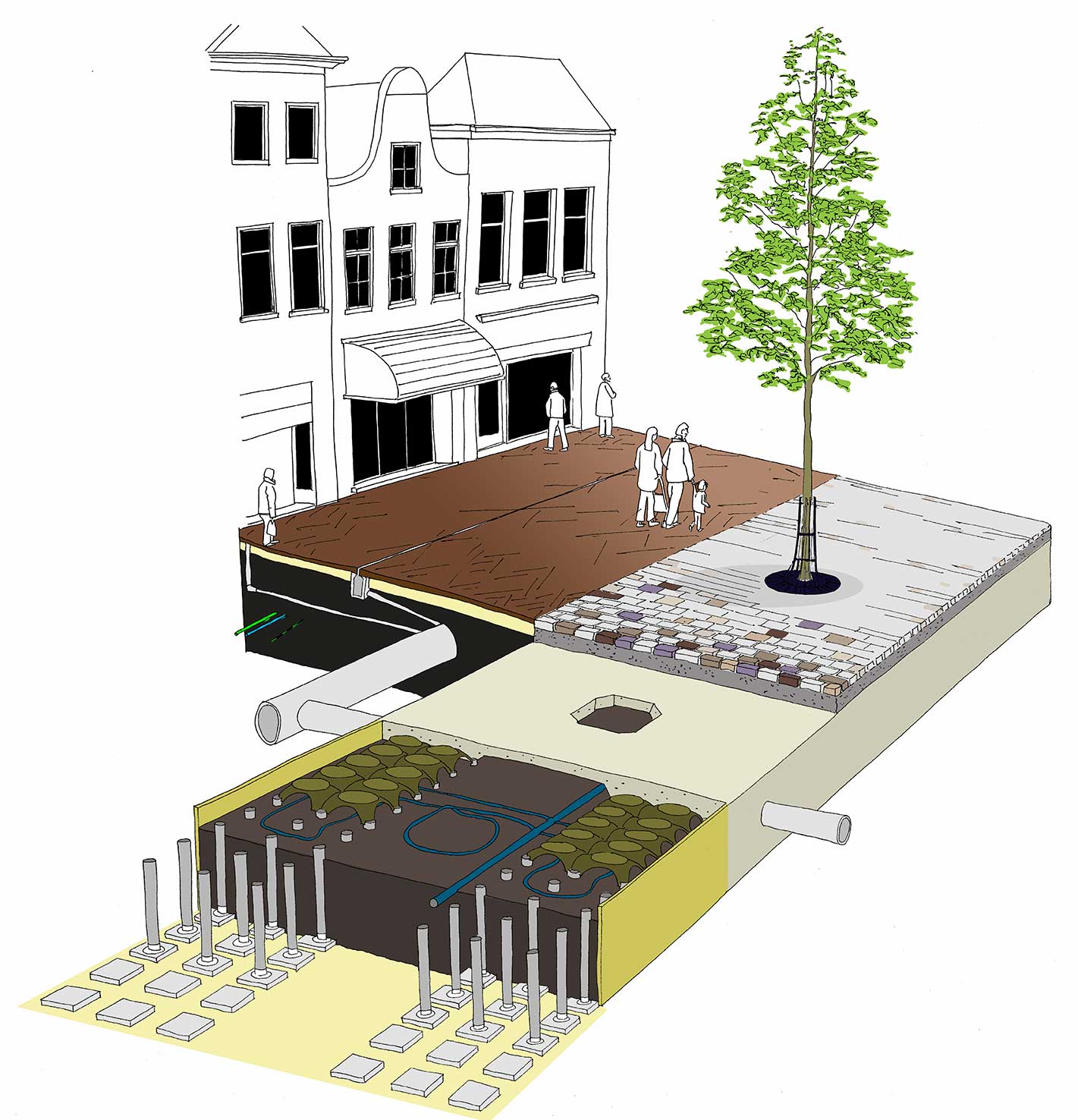

Optimising the use of materials not only reduces construction costs, but also minimises environmental impact. Daliform solutions allow efficient use of materials while ensuring excellent structural performance. One example is the enormous amount of concrete saved on every construction site thanks to the Iglu’®, Atlantis and U-Boot®Beton systems.

Resilient buildings and hydraulic risk management

Building resilience is the ability to withstand and adapt to unforeseen natural events or climate change. Daliform Group’s permanent formworks increases the durability and adaptability of buildings and infrastructure, ensuring safety and comfort for users.

Effective water management is crucial to prevent flooding and structural damage.

Solutions such as Atlantis Tank are an integral part of a climate change adaptation strategy that is crucial for modern cities grappling with water management issues.

Through innovation, we continue our journey to make green building more affordable for everyone.