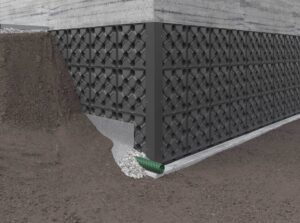

Superior performance and durability, Iglu’® Barrier is a recycled plastic panel created to protect the waterproof layer in the walls against the ground.

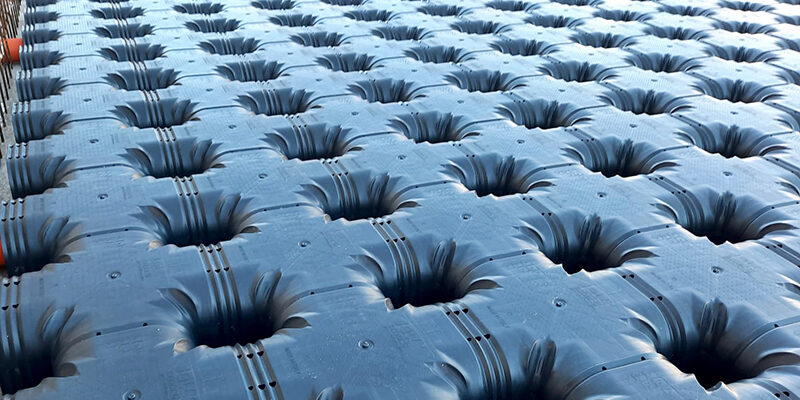

Thanks to its technical specifications, it guarantees excellent compressive strength by creating a ventilated cavity and avoids contact between the ground and the waterproofing of the retaining wall.

Walls against the ground are exposed to humidity due to capillary action, to which can be added the possible condensation of humid air as a consequence of inadequate thermal insulation.

This situation can lead to the formation of mould, unpleasant odours and above all compromise the durability of the structure.

Iglù® Barrier finds application in various areas, protecting against water infiltration and rising damp.

Ideal for underground areas such as garages, cellars and other underground areas.

Among the several benefits, some peculiar aspects might be highlighted as follows:

Comfort

The resulting air chamber that is created protects from temperature changes, reducing the “cold wall” effect. Thus, heat loss may be reduced, contributing to energy savings.

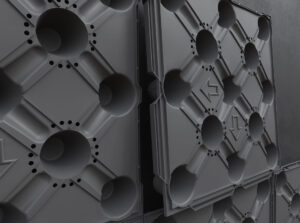

Superior protection and resistance

Made of high-strength materials, Iglu’® Barrier acts as a barrier for foundations against penetrating damp, condensation and other atmospheric agents, preserving the structural integrity of buildings.

Sustainability

Daliform Group, who plays an active role in sustainability issues, collaborates with professionals and institutions to spread environmentally friendly construction practices. Iglu’® Barrier is one of them, providing projects with environmentally friendly perimeter protection.

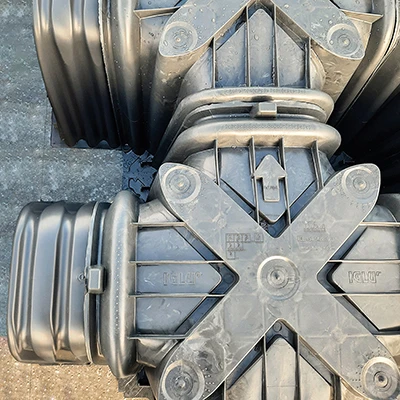

Ease of installation

The modular and intuitive design allows for quick and simple installation, reducing construction time and costs, as well as increased safety in the excavation covering process due to excellent compressive strength.

Versatile applications

Iglu’® Barrier adapts to different foundation configurations and soil types, making it ideal for both residential and commercial buildings.