A sustainable future with clean energy and recycled plastic products.

In a world that is facing the challenge of climate change and responsible resource management, we at Daliform Group are committed to concrete green choices. We have embarked on a path of energy sustainability, choosing to power our production processes with 100% green energy from renewable sources. This means that the energy we use to manufacture our products is CO₂-free, contributing significantly to reducing our environmental impact.

The use of clean energy is a conscious choice, aimed not only at reducing harmful emissions, but also at promoting an environmentally friendly corporate culture. This commitment enables us to play an active role in creating a greener, sustainable and planet-friendly economy.

Recycled plastic: an added value for our products.

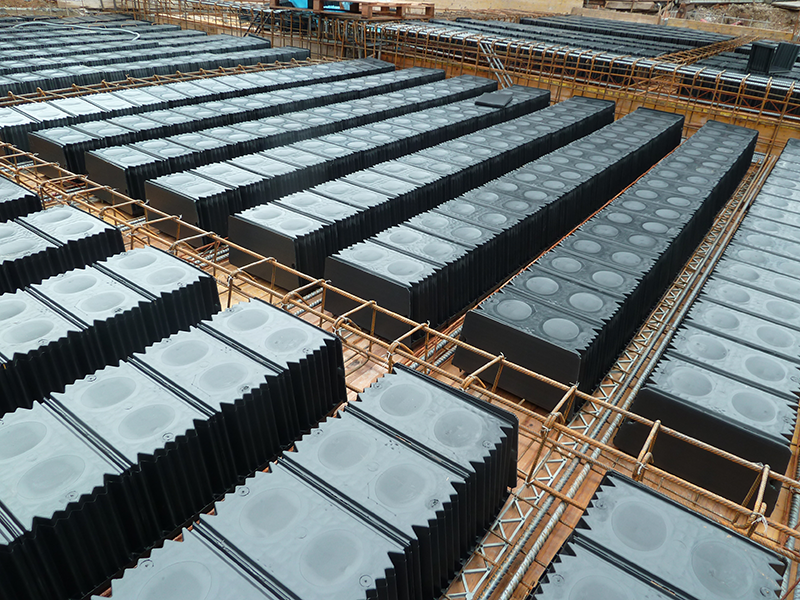

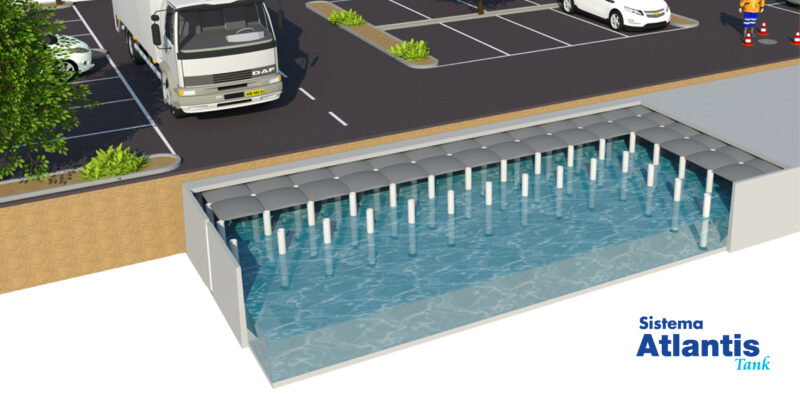

The other key pillar of our green strategy is the use of recycled plastic. Our products, such as our permanent formwork systems, are designed to offer high performance and durability while minimising environmental impact. The use of recycled plastic does not compromise the quality of our products; on the contrary, it adds value in terms of sustainability, responding to the growing demand for environmentally friendly materials from the market and our customers.

The benefits of our choice.

- Reduction of CO₂ emissions: by using renewable energy, we contribute significantly to the reduction of greenhouse gas emissions, limiting the impact of the production process on global warming.

- Waste minimisation: the use of recycled plastic in our production helps reduce the amount of plastic waste in the environment, extending the life cycle of materials and supporting the principles of the circular economy.

- Innovation and sustainable quality: our recycled plastic products maintain high standards of quality and performance, meeting the technical requirements of the construction and engineering sector, but with added value: reducing environmental impact.

- Social commitment: adopting a sustainable production model means not only respecting the environment, but also generating value for the community, demonstrating that it is possible to combine innovation and respect for the planet.

Towards a greener future

Our commitment does not stop here. We look to the future with the understanding that sustainability is not an end point, but a continuous process of improvement. We will continue to invest in green solutions and promote sustainable practices in all areas of our business.

We are convinced that change starts with small and big choices we make every day.

And choosing to use clean energy and recycled plastic is our answer to the climate challenge.