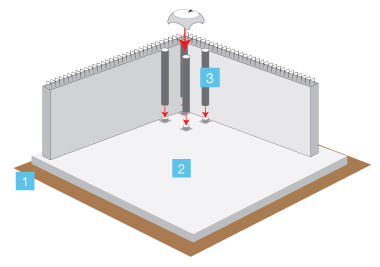

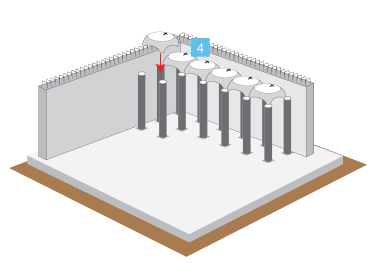

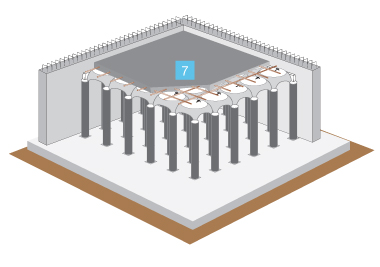

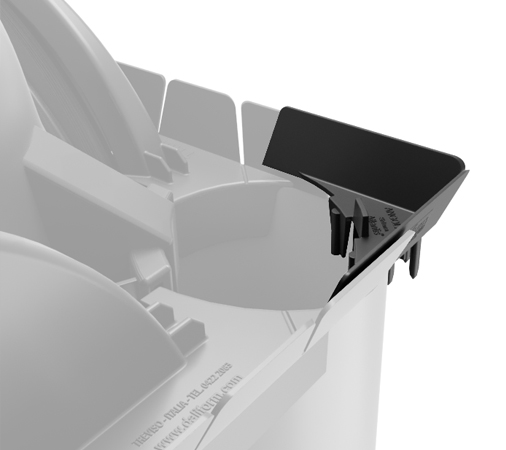

Sistema Atlantis (Atlantis System) is an advanced system for creating cavities in general, under-floor cavities and ventilated crawl spaces in newly constructed or restructured civil and industrial buildings, accumulation tanks, dispersion tanks, honeycomb rafts, low temperature cold rooms.

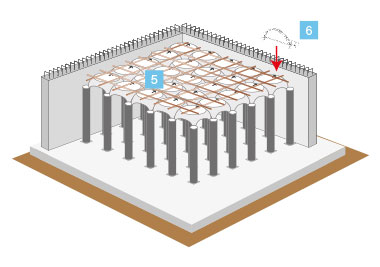

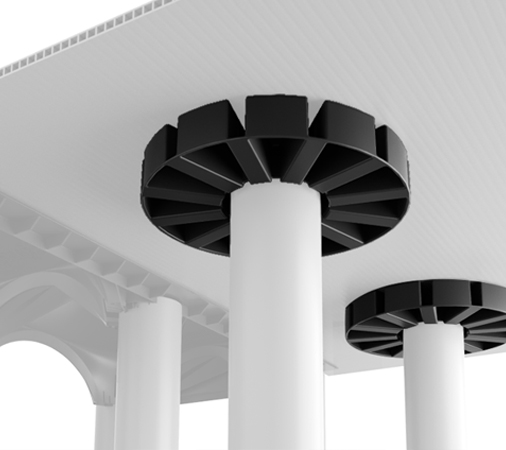

The Atlantis System, made of recycled plastic, is used when the depth of the crawl space or sub-floor cavity is too high to allow the use of classic Iglù® formwork, with the advantage that the constant diameter of the elevator pipes makes it possible to minimise the use of concrete for filling. The main system features are speed, simplicity and cost performance.

Furthermore, with Atlantis, a sanitary space is obtained with a suitable humidity barrier and, if properly ventilated through piping connected outdoors, it is a tool for the disposal of the Radon gas present in the ground.