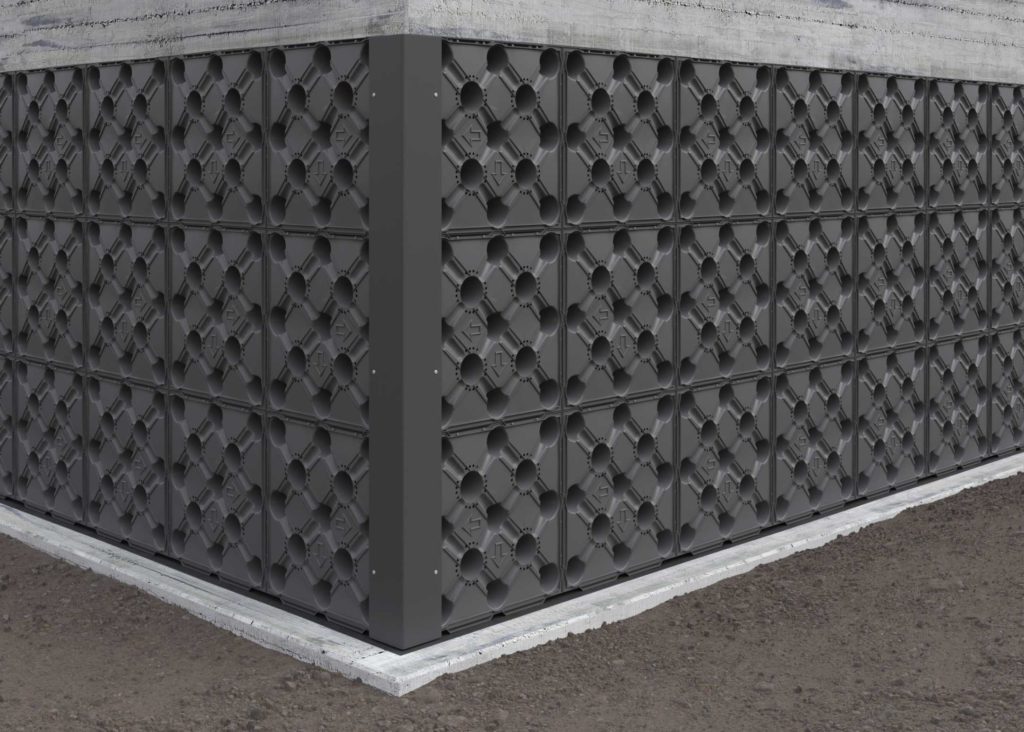

This system is the safest way to protect below-ground walls which are intended to last over time and will accompany the structure throughout its service life.

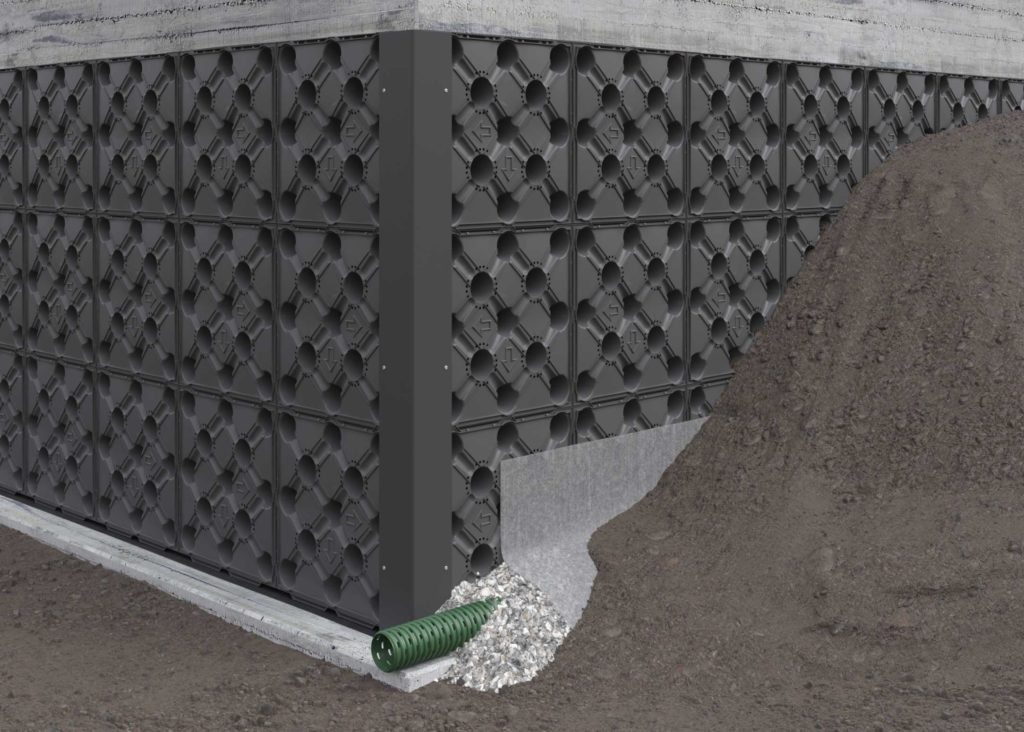

Retaining walls and other walls that are in contact with the ground are exposed to damp due to capillary action; added to this is the possibility of damp air resulting from inadequate thermal insulation. This situation can lead to the formation of mould, unpleasant odours and, more importantly, it can compromise the durability of the structure.

It is therefore imperative to select materials that maintain their impermeability to water and water vapour as well as their rot-resistance and mechanical strength over time, even when under loads from construction-site vehicular traffic.

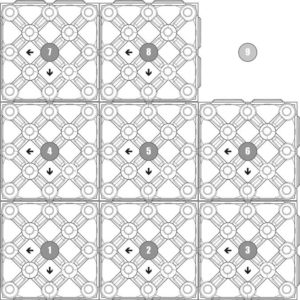

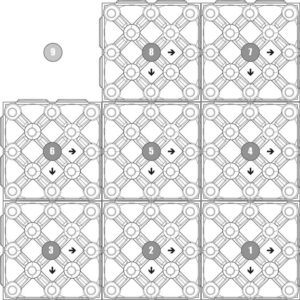

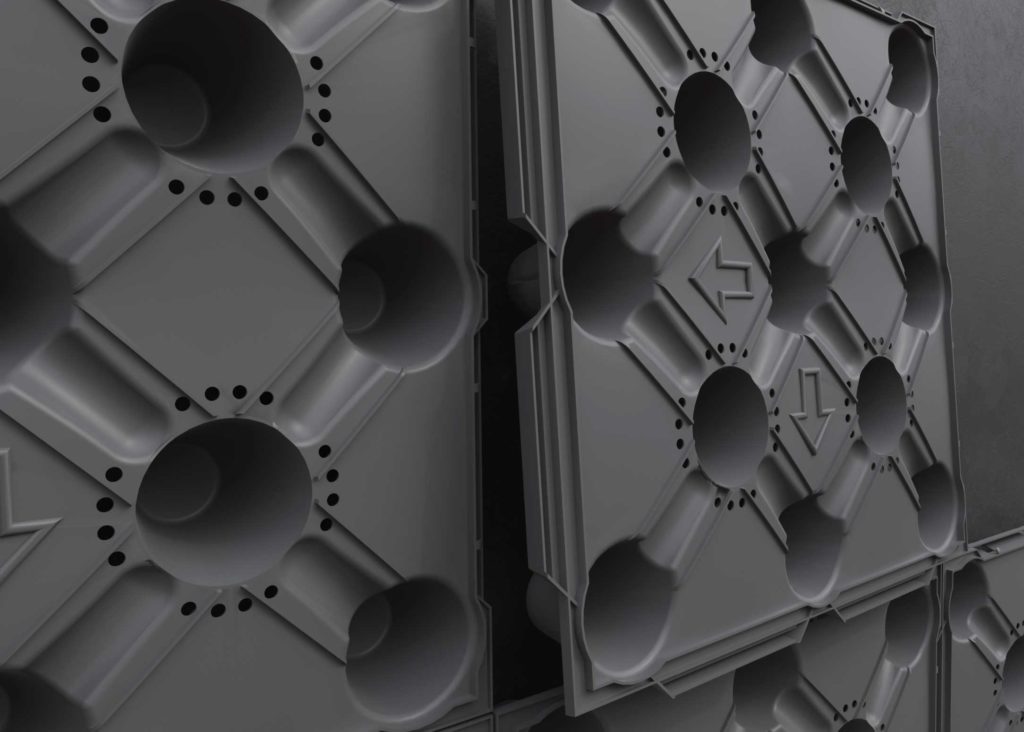

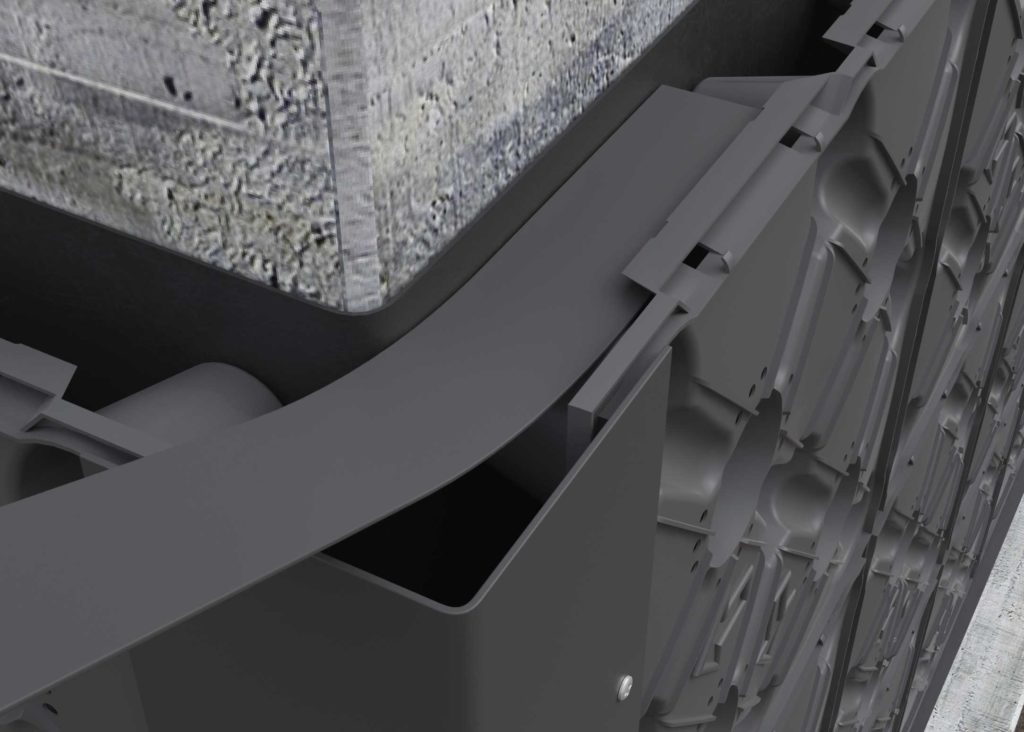

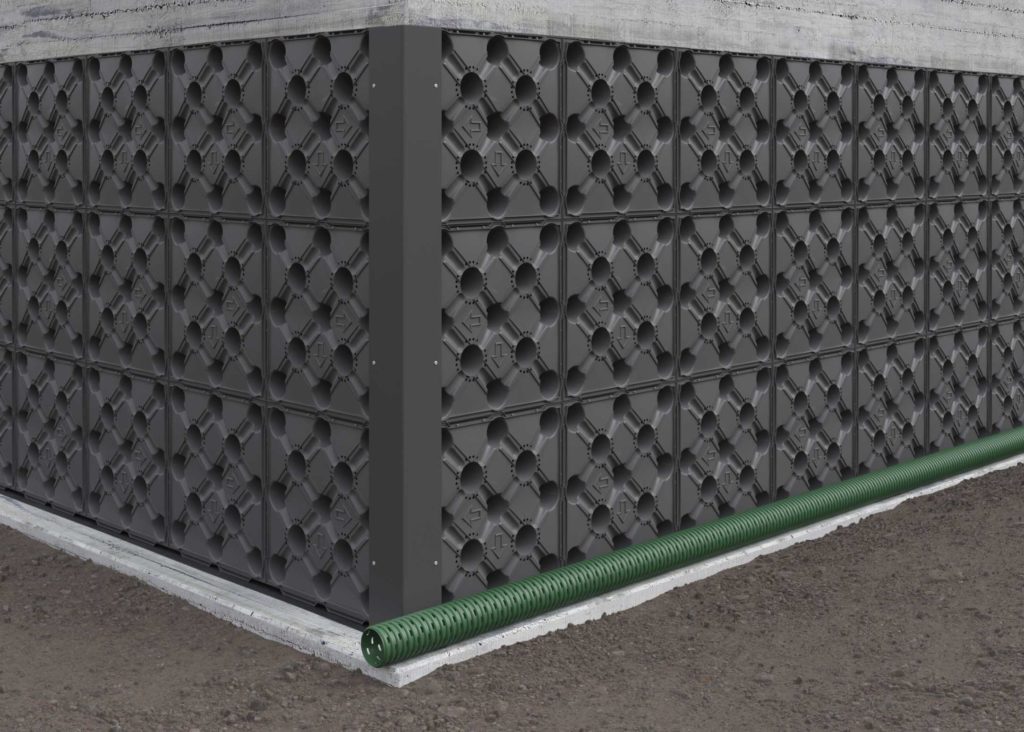

Iglu’® Barrier is a recycled plastic panel built to protect the waterproof layer of retaining walls. By virtue of its technical characteristics, it guarantees an excellent resistance to compression.

The Iglu’® Barrier creates a ventilated space between the waterproof retaining wall and the backfill, therefore eliminating contact between the ground and the waterproofing.