يتسبب التدعيم المستمر المرتبط بالزيادة المستمرة في كثافة الاستيطان، على الرغم من أنه ضروري للتنمية البشرية، في إحداث تغييرات كبيرة في نظام المياه السطحية والجوفية.

جانب آخر يجب أخذه بعين الاعتبار هو تغير المناخ، حيث يؤثر ارتفاع درجات الحرارة أيضًا على أنماط الطقس. وتتمثل الآثار الأكثر وضوحًا لهذا الاتجاه المناخي في هطول أمطار أكثر عنفًا وكثافة في فترات شديدة التركيز، تليها فترات طويلة من عدم هطول الأمطار وما يترتب على ذلك من جفاف. ويؤدي هذا التطرف في الظواهر إلى زيادة كبيرة في احتمال حدوث الفيضانات، بسبب الفيضانات الغزيرة والمفاجئة بشكل متزايد.

تحول غلق التربة أولاً وقبل كل شيء دون امتصاص التربة لمياه الأمطار، مما يقلل من وقت الجريان السطحي وبالتالي يجلب المياه بشكل مفاجئ إلى المسطح المائي المستقبل. بعض المشاكل الناتجة عن ذلك هي:

انخفاض احتياطي المياه: من خلال تلقي كميات أقل من مياه الأمطار، تنخفض مناسيب المياه الجوفية مع خطر جفافها.

الحمل الزائد في المجاري: يمكن أن تؤدي الزيادة المفاجئة في حجم المياه التي يجب التخلص منها إلى تعريض وظائف النظام للخطر، مما يؤدي إلى حدوث فيضانات وتكاليف اجتماعية.

جودة المياه: مع تدفق المياه عبر المناطق الحضرية، ستصبح ملوثة بشكل تدريجي، مما يؤدي إلى زيادة هدر مياه الشرب.

مخاطر الفيضانات: على نطاق أوسع، يمكن أن تنهار أحواض الأنهار أيضًا مما يؤدي إلى حدوث فيضانات غالباً ما تكون لها عواقب مأساوية.

في السياق الذي أصبح فيه الثبات الهيدروليكي معيارًا في الإنشاءات الجديدة وبالتالي في بناء خزانات تجميع المياه وتصفيحها، يوفر نظام أتلانتس حلاً عمليًا وفعالًا لتحقيق ذلك.

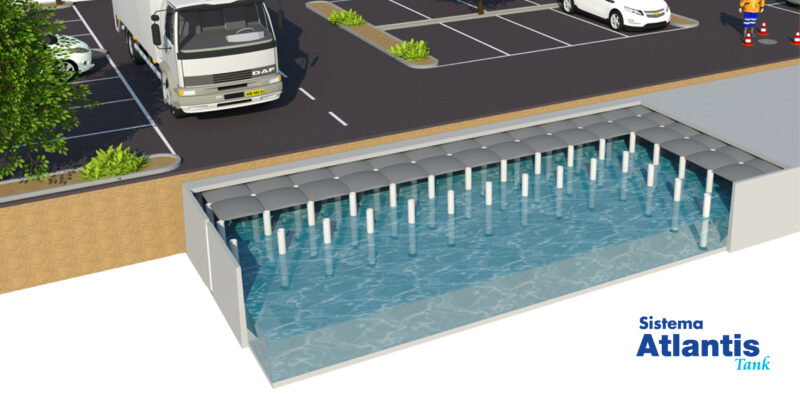

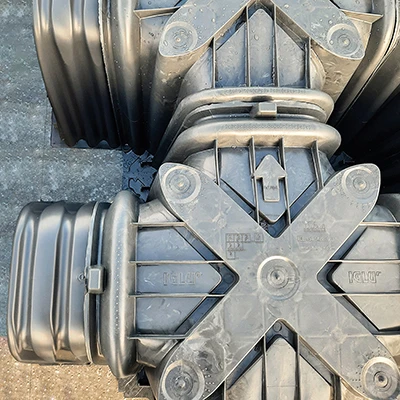

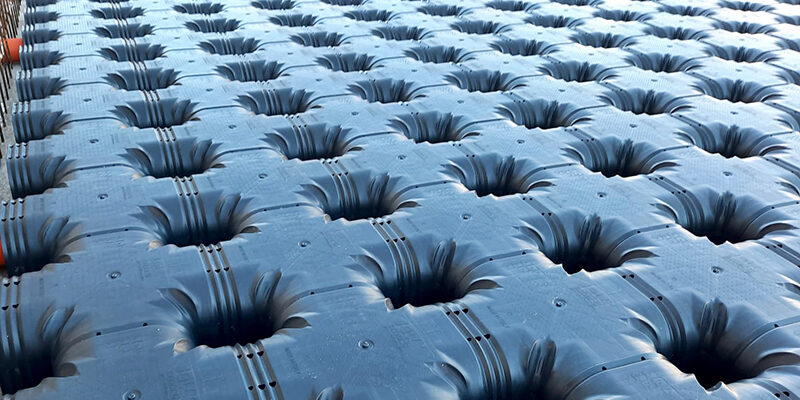

بفضل نظام أتلانتس، يمكن إنشاء خزانات لتجميع مياه الأمطار، خزانات للتشتت، وصوبات لإعادة تدوير المياه. تتكون الخزانات المصنوعة من الخرسانة المسلحة من بلاطة وجدران محيطية وبلاطة مدعومة بأعمدة، وهي مصممة لدعم أنواع مختلفة من الأحمال، مثل أرصفة المشاة، المساحات الخضراء، أو مواقف السيارات.

يمكن بناؤها تحت الساحات الأمامية، الطرق، ومواقف السيارات، سواء التجارية أو الصناعية، وهي مصممة للتخفيف من تأثير الفيضانات الناجمة عن الظواهر الجوية الاستثنائية. وهذا يعيد إلى التربة قدرة الصرف التي سلبتها الخرسانة منها، دون أي تأثير بصري أو بيئي.

تؤكد التشريعات في مجال حماية المياه على الحاجة إلى بناء مستجمعات المياه وخزانات تشتيت المياه لتفادي خطر الفيضانات، ناهيك عن أن مسألة التحويل المستدام للأراضي أصبحت ذات أهمية متزايدة.

يمكن للسلطات العامة، على سبيل المثال، الحصول على مزايا كبيرة من بناء خزانات لتشتيت مياه الأمطار: أولاً، يتم إثراء جداول المياه الجوفية بدلاً من تجفيفها؛ ولا توجد حاجة لزيادة حجم شبكة الصرف الصحي بما يتناسب مع توسع المدينة؛ وأخيرًا، يمكن أن يسمح تحليل التكلفة/الفائدة الذي يشير إلى منطقة معينة – مثل البلدية، المقاطعة، أو حوض النهر – بتنفيذ خطة إعادة تطوير هيدروجيولوجية شاملة، وبالتالي تقليل خطر الفيضانات بشكل كبير.